Like most companies, Dobbin’s design process really starts with fabric. Our first step is to visit the offices of various fabric agents in New York City, and to contact the fabric mills and agents we’ve worked with in places like Los Angeles, Paris and even New Jersey. Fabric agencies are small — usually just one or two people — but they each represent multiple fabric mills across Europe and Asia. While mills employ agents all over the world, the agents in New York usually service the entire USA, part of what’s kept the Garment District the epicenter of the American fashion industry.

Small designers like us tend to buy more expensive European fabric ($11-$30/yard.), because the minimums for ordering are more achievable and because we prefer the high quality of these textiles. Many of the Italian mills we use have been in business for over 100 years, and have vast experience and technology for producing the best textiles on earth.

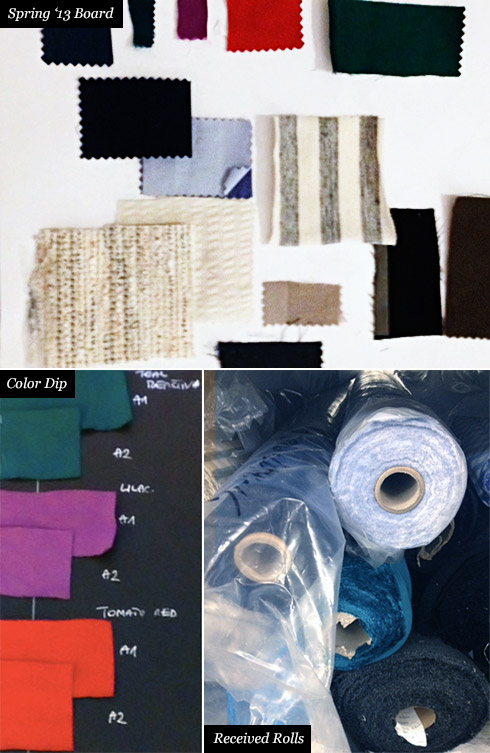

At agents’ offices (and at fabric shows in NYC), Catherine and I start collecting headers (fabric samples stapled to labeled card stock) and corresponding pricing lists of the fabrics we think might fit our line. Once we have a pile of contenders, we spend days going through the fabrics carefully, looking for the best feeling, most wearable, washable, and luxurious of the bunch. We also scrutinize each mill’s color card for each fabric to see what might work for the season’s colors, and keep a careful eye on pricing so that we don’t fall in love with fabrics that would push us outside of our price range (lest we have to pass the cost on to customers).

At Dobbin, we’re typically looking for thicker, stretchy fabrics that have both structure and ease. We favor knits, pant fabrics like stretch twill, canvas and flannel, and different kinds of silk for shirting. We go through the process of boiling down the heap of fabrics to our favorites to create a comprehensive collection in which the pieces, fabrics and colors all work together.

At that point, we then have to re-contact fabric agents to find out the fabrics’ availability and minimums. If the fabrics we like won’t arrive on time for production for the season, or if a mill’s minimum for ordering is too high, we then go back to the drawing board to find a similar replacement. It’s kind of like a jigsaw puzzle; throughout the design process, we’re constantly piecing together the very best collection we can, with changes to one piece in turn causing changes in any number of others. Large companies have sizable design, sourcing, pattern making, production and merchandising teams that work together to find and choose fabrics. In our case, it’s just the two of us doing the same thing, though on a smaller scale. At this point, because we only have two seasons of customer data and feedback, we’re also operating more on instinct than on numbers, as a larger company likely would.

The next step is ordering sample yardage (usually about 10 yards of each fabric). Our pattern maker uses the sample yardage for draping, pattern making and sampling. If we’re on a very tight timeline (which we usually are!), we sometimes have to order the larger run of fabric we’ll actually be using for production, and simply cut some yardage off the end for sampling.

A large UPS bill later, bolts of fabric start to show up at our office. That kicks off the pattern and sample-making process, which we’ll be covering in the next post!