Having covered some ground in explaining our fabric selection process at Dobbin, I now want to bring you forward to a more real-time part of the production process: pattern making.

Since our last entry, we’ve received most, but not all of our Spring 13 Production fabrics. We’re still waiting for some of our new pant, dress and blouse fabrics that we need to complete the collection. We are constantly emailing, calling (and sometimes begging!) fabric agents for updates. It usually all comes together; throughout the process our small team continues to regularly communicate about how best to deal with unexpected turns in the road.

While we deal with fabric hiccups, we’ve also started working with our pattern maker. She works with us on a freelance basis while she works full-time for a mass manufacturer. She’s been in the fashion business for almost 40 years, and is an expert in creating patterns for everything from jeans to red carpet gowns.

Of course, working with her on a part-time basis makes for a lot of schedule juggling, so that’s yet another part of the production puzzle! Many small companies like us use freelance pattern and sample makers because they can’t yet afford to employ them full-time. The other option is to use a pattern service, which is an office of pattern and sample makers and sometimes cutting rooms and production sewers. Pattern services work with small companies and even with larger ones who are in a rush to get a new product to market, and who need an additional resource beyond their in-house pattern makers. Pattern services can be very busy places; we tried working with one, and just felt that our patterns and samples did not get the TLC we demand goes into our Dobbin products.

It’s very hard to find a good pattern maker whether you’re a small or a large company. Pattern making itself has changed a good deal in the past 20 or 30 years. Before patterns could be created by computer programs like CAD (Computer Aided Design), they were all created by draping fabric on a dress form and then drawing up the pattern on paper by hand. Now, many companies who produce on a large scale prefer to use CAD. Patterns are created digitally and sent directly to sample makers or factories for sampling. Many companies who care deeply about the fit of their garments prefer the old-school pattern making techniques. To us, these patterns have more dimensionality and attention to the contours of the body. This kind of pattern making is as much of an art as it is a science.

The dilemma with requiring these techniques is that they’re used mainly by pattern makers who have an enormous amount of experience. And as they retire, there are fewer and fewer of these workers. Younger pattern makers who have graduated from Parsons, FIT or other fashion schools’ pattern making programs either lack experience and knowledge or they work primarily via computer. I’d encourage young people who are interested in a fashion career to think about this lucrative field, and to learn both ways of pattern making. It’s a great job, and one that the fashion industry cannot live without.

In the next post, I’ll touch on how we design our clothes and the considerations we make in the look and fit of each of our products. For now, I will skip that part and do a quick run-down of the beginning stages of working with our pattern maker.

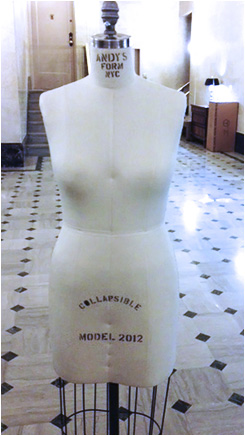

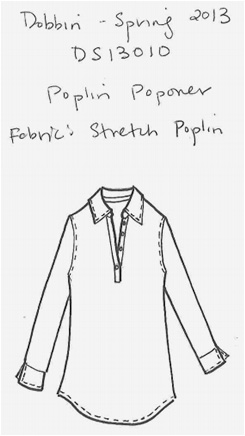

With our sketches, we also hand over optimal measurements for each garment we’ve designed. Our pattern maker then takes the sketches and uses our specially made dress form to create Dobbin-specific patterns.

A few patterns are created at a time. We pick them up from the pattern maker, and then deliver sample fabric and trim (buttons, lining, zippers, etc.) to our sample maker, who sews them for us. We then schedule a fitting, during which Catherine (co-founder of Dobbin and my business partner), our pattern maker and I see the samples on a fit model. We discuss what’s right and wrong about the fit and the feel of the garment, and then our pattern maker goes back and makes the corrections on the original patterns. After the corrections, we make another sample and fit again. We do this three or four times until the fit is perfect, with weeks in between each fitting. We want the fit to be flawless and we won’t settle for less, so the pattern and sample process tends to be the most stressful part of the production process.

Left: The specially made Dobbin form

Right: Sketch from the Spring 2013 range